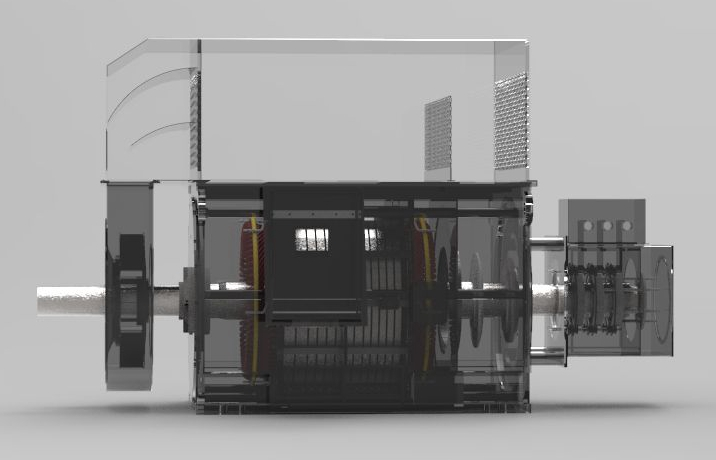

YR Series Wound Rotor Three-Phase Asynchronous Motor is an optimized series of products developed by our company after digesting and absorbing the design and manufacturing technology introduced from Westinghouse of America and LDW of Germany, and combining our more than 70 years of long-term stable design and manufacturing experience of high-voltage three-phase asynchronous motor, and can have YRKK and YRKS series according to different cooling methods to meet the requirements of different cooling methods.

Product Overview

YR Series Wound Rotor Three-Phase Asynchronous Motor is an optimized series of products developed by our company after digesting and absorbing the design and manufacturing technology introduced from Westinghouse of America and LDW of Germany, and combining our more than 70 years of long-term stable design and manufacturing experience of high-voltage three-phase asynchronous motor, and can have YRKK and YRKS series according to different cooling methods to meet the requirements of different cooling methods.

This series motors can be widely used to drive many kinds of general-purpose machines, such as compressors, pumps, crushers, cutting machines, transportation machinery, coal mills, steel rolling mills, winches, belts, hoists and other heavy load machines. It is widely used in various industrial and mining industries such as mining, machinery industry, petrochemical industry, power plant, etc. as the prime mover.

Advantages and Characteristics

1. The insulation level of this series motor is F grade, using the domestic first-class rubber less insulation system. Using high-quality mica tape, environmental protection impregnating resin paint, in the CNC winding machine, pulling machine and wrapping machine to complete the coil production, and finally by VPI vacuum pressure impregnation treatment. It is characterized by low normal dielectric loss, low high temperature dielectric loss, low leakage current of the whole machine, and very low voltage drop rate in thermal aging. Therefore, the coils are well made, with excellent and reliable insulation performance, good mechanical strength, and strong moisture resistance.

2. After absorbing and digesting the advanced technology at home and abroad, the company uses the "field and circuit" combination method for the electromagnetic design of this series, which improves the calculation accuracy of electromagnetism and can provide accurate maximum torque multiplier, and the overload capacity of the motor is effectively guaranteed. Using FEM mechanical analysis method for structural design, and constantly verified by practice, can accurately apply boundary conditions to the established mechanical model, thus solving the accuracy of material use, control the vibration and noise of the motor; at the same time, FEM mechanical analysis method is applicable to various cooling methods, high accuracy and intuitive air volume distribution, improve the level of temperature rise calculation in motor design, reduce ventilation loss, and improve motor efficiency.