Y, YKK series high-voltage three-phase asynchronous motors (frame size 355~1120mm) are a series of products developed by our company by introducing advanced technology at home and abroad, adopting modern advanced field analysis technology for electromagnetic calculation, and making fine calculation and optimal design for various losses, wind resistance and strength of each component of the motor. The series of products are developed through mature and reliable design and production system, combined with more than seventy years of experience in manufacturing medium and large high-voltage AC motors; with high-quality materials and scientific processing technology in manufacturing, the motors have the advantages of high efficiency, low noise, low vibration, high reliability and easy installation and maintenance.

Product Overview

Y, YKK series high-voltage three-phase asynchronous motors (frame size 355~1120mm) are a series of products developed by our company by introducing advanced technology at home and abroad, adopting modern advanced field analysis technology for electromagnetic calculation, and making fine calculation and optimal design for various losses, wind resistance and strength of each component of the motor. The series of products are developed through mature and reliable design and production system, combined with more than seventy years of experience in manufacturing medium and large high-voltage AC motors; with high-quality materials and scientific processing technology in manufacturing, the motors have the advantages of high efficiency, low noise, low vibration, high reliability and easy installation and maintenance.

The series products are mainly used in general mechanical equipment such as fans, pumps, compressors, crushers, scrap shredders, belt conveyors, transportation machinery or other similar mechanical equipment in petroleum, chemical, coal, power station, metallurgy, transportation, textile, pharmaceutical and grain processing industries.

Advantages and Characteristics

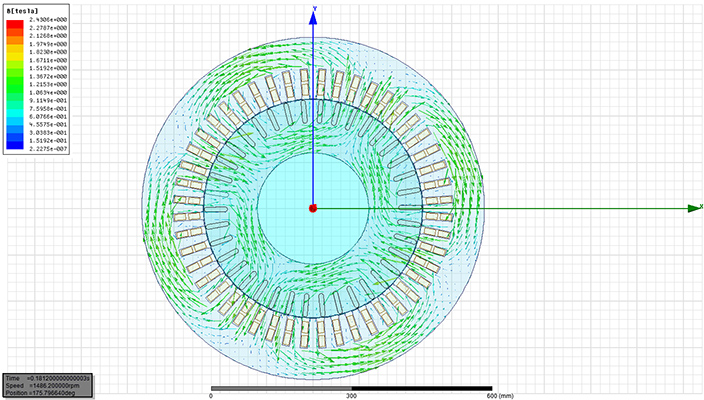

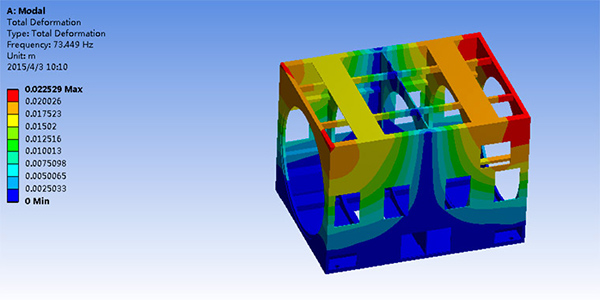

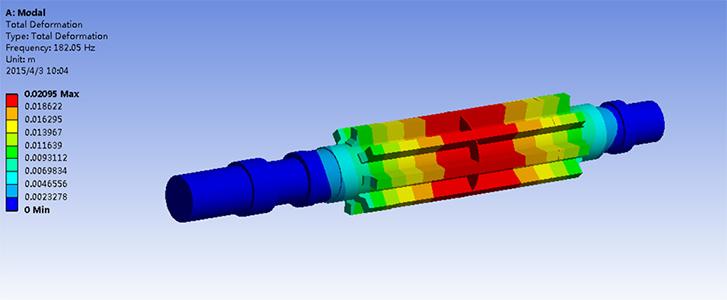

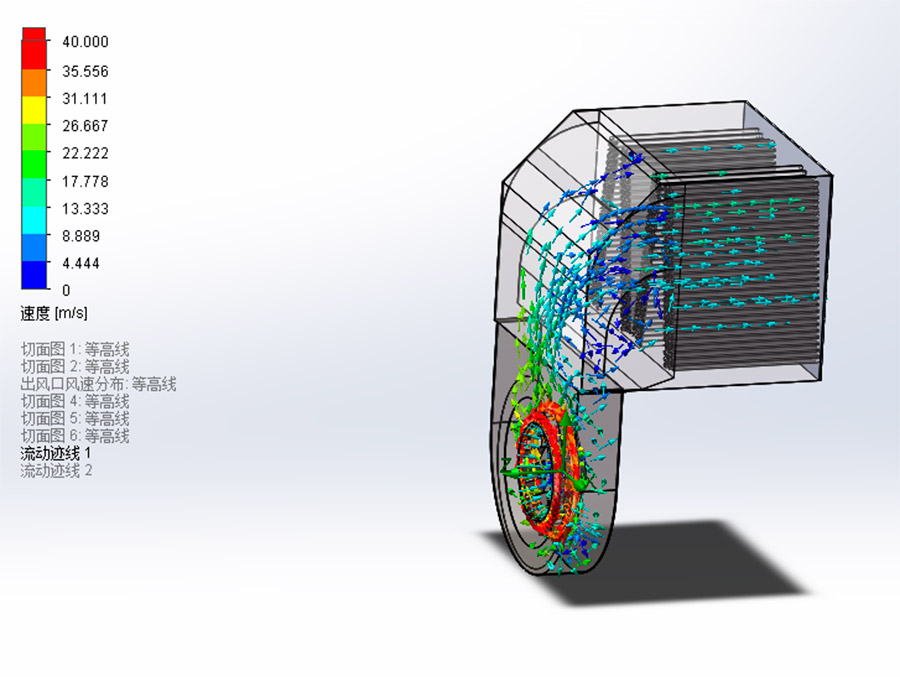

1. After introducing and absorbing the advanced technology at home and abroad, the company uses the "field and circuit " combination method for electromagnetic design of this series, which improves the calculation accuracy of electromagnetism and can provide accurate maximum torque multiplies, and the overload capacity of the motor can be effectively guaranteed. We use FEM mechanical analysis method for structural design, and constantly verify by practice, can accurately apply boundary conditions to the established mechanical model, thus solving the accuracy of the use of materials, controlling the level of vibration and noise of the motor; at the same time, FEM mechanical analysis method is applicable to various cooling methods, with high accuracy and intuitive air volume distribution, improving the level of temperature rise calculation in motor design, reducing ventilation losses, and improving motor efficiency.

|  |

| Electromagnetic analysis diagram using the "field and circuit" combination method | Output curve of electromagnetic calculation |

|  |

| Finite element mechanical analysis method for machine base | Shaft system analysis |

Modeling and analysis of external air path by finite element analysis method

2. This series of motor adopts box structure, the base is made of steel plate welded into box shape, light weight and good rigidity, the top of the motor is installed with protective top cover or cooler, which is convenient for motor heat dissipation, installation and maintenance.

3. The stator adopts external press-fit structure, and the stator and rotor punching sheets are made of low-loss non-oriented cold-rolled silicon steel sheets. The stator winding is made of class F insulation material, which has strong insulation voltage resistance and anti-corona ability, and the winding ends are reliably fixed and tied, and treated with vacuum pressure impregnation solvent-free paint (VPI), so the motor has excellent and reliable insulation performance, high mechanical strength, strong moisture resistance and long service life.

4. The bearings are in the form of rolling bearings and sliding bearings, depending on the power and speed of the motor, and the protection level is IP00, IP23, IP44, IP54 or IP55. The rolling bearing is equipped with a non-stop oil filling and draining device, making it easy for users to use and maintain.

5. The main junction box is placed on the right side of the motor (from the DE), or on the left side according to the user's requirements, and there are separate grounding terminals inside and outside the junction box.

6. According to the user's requirement, temperature measuring devices can be added to the important parts such as stator winding and bearing to facilitate on-site observation and remote monitoring to ensure safe and reliable operation of the motor.