Product Overview

TDMK Series of Large AC Three-phase Synchronous Motors for mining mills are the core driving equipment for mining, cement and other industries, and they are also the main products developed and produced by our company since the establishment of the factory in 1946. This series of motors (including TDMK series brush synchronous motors and TMW series brushless synchronous motors) are widely used in mining, cement and other industries because of the characteristics of large starting torque. It is mainly used to drive mechanical equipment with lower speed and higher power, mainly driving lattice type ball mill, rod mill, coal mill, etc.

Our company combines more than 70 years of experience in manufacturing medium and large high-voltage AC motors, and adopts advanced technology at home and abroad for the characteristics of the mining industry, and through a mature and reliable design and production system, adopts new technology, new materials and new technology to continuously improve the product design and manufacture, and selects materials carefully and manufactures well, so that this series of products become more reliable, more compact, less vibration, lower noise, more suitable for outdoor use, more light weight and more reliable. It is a mature product with more reliable operation, more compact structure, less vibration, lower noise, more outdoor application, lighter weight and higher efficiency.

This series of synchronous motor conforms to GB755 "Rotating Motor Quotas and Performance" and JB/T1473 "Technical Conditions for Large AC Three-phase Synchronous Motor for Transmission Mines". The power level and installation size conform to our standard and IEC standard of International Electrotechnical Commission, and conform to German standard, and can be used for the matching of export equipment and the replacement of imported products.

TDMK series synchronous motor excitation system adopts silicon controlled excitation device with slip ring and brush structure.

The excitation system of TMW series synchronous motor is composed of AC exciter rotating coaxially with the main motor and rotating rectifier disc, without slip ring and brush structure, there is no problem of brush replacement and slip ring wear, and it can adapt to harsh environment.

Voltage level: 3kV~11kV and other voltage levels of the series motor specifications.

The motors can be started directly at full voltage or softly with reduced voltage.

| Power range | 400-15000kW |

| Number of poles | 60,48,40,36,32,30,24,20 |

| Synchronous speed | 100,125,150,167,187.5,200,250,300r/min |

| Frame size | 4250,3250,2900,2600,2150,1730 |

| Frequency | 50/60Hz and frequency conversion |

| Cooling mode | IC01, IC37, IC81W |

| Protection level | IP00,IP20,IP21,IP23,IP44,IP54,IP55 |

| Structure and installation type | IM7311 |

| Standard | IEC,GB |

The motor is divided into two types: shaft punching motor and non-punching motor, shaft punching motor needs to be used with pneumatic clutch.

Shaft non-perforated motors have high starting performance.

At rated voltage: starting torque x 1.7 times (0.6 for shaft perforation)

Draw-in torque x 1.0 times (0.6 for shaft perforation)

Lost step torque x 2.0 times

Starting current x 7.0 times

The performance indexes, mounting and external dimensions of the outdoor (W), humid tropic zone (TH) and outdoor humid tropic zone (THW) motors derived from the series are the same as those of the basic series.

Advantageous Features

1. Advanced Optimization Design Means

Combined with our long-term successful technology of producing medium-sized high-voltage motors, we adopt advanced design means to optimize the design of TDMK series three-phase synchronous motors.

|  |

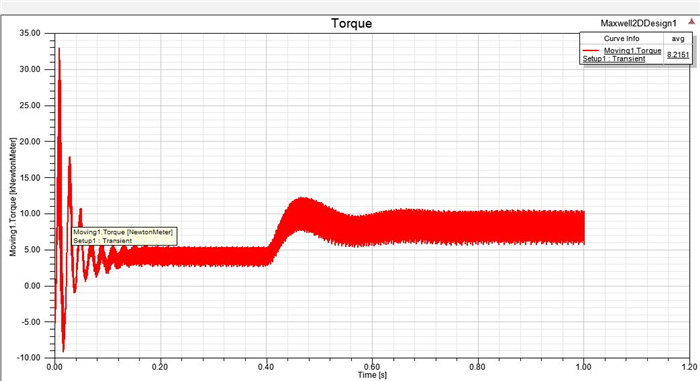

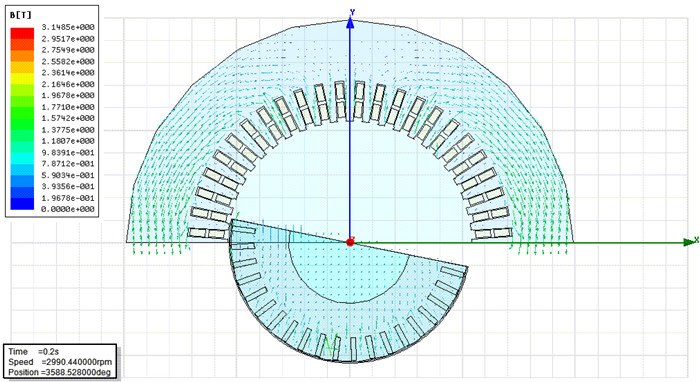

| Magnetic Field Analysis | Performance Analysis |

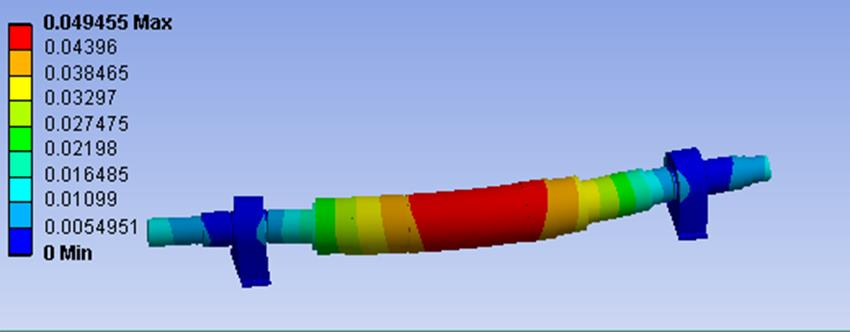

Shaft system calculation

2. Reliable Motor Manufacturing Technology

2.1 The motor base is made of Q235B high-quality steel plate welded. The design of motor parts are analyzed by finite element modeling and verified by test, with good rigidity, light weight and stable structure.

Low vibration, high precision machining of rotating parts to ensure concentricity of stator and rotor.

Low noise, seat stress relief technology ensures the stability and dynamic performance of the seat.

2.2 The stator core is made of 0.5mm thick low-loss silicon steel laminated with radial ventilation channels separating the core sections.

2.3 The stator winding is insulated with mica tape. After the winding is installed, vacuum pressure immersion paint (VPI) is applied to the whole stator, and the winding insulation grade is F, which has a good temperature rise margin. The coil slot fixing method and connection method of LDW advanced technology are introduced to ensure the long-term operation reliability of the motor.

2.4 The coil temperature measuring element, bearing temperature measuring element, vibration measuring probe, cooler water leakage detection device, etc. collect operating information at any time and deliver it to the control system exclusively to ensure that the motor is effectively monitored by the system.

2.5 The magnetic pole core is made of 1.5mm thick steel plate laminated. The magnetic pole wire gauge, damping strip and damping ring are made of high quality copper, and the magnetic pole coil is insulated with class F. The magnet pole coil connection and damping ring connection are hard brazed.

2.6 The motor uses domestic and foreign high-quality bearings, long bearing life, simple maintenance bearing stability is good, simple and convenient daily maintenance.

2.7 Higher mechanical performance, high temperature rise design margin, the same motor can meet the requirements of a variety of working conditions. Installed with anti-condensation shutdown space heater to facilitate daily maintenance.

2.8 AC exciter and rotating rectifier adopt independent structure, easy to maintain and repair. The rotating rectifier disc is small and compact, with electrical connections, structural fixings and electrical heat dissipation parts integrated, and each flap is insulated from each other, which makes operation reliable, low failure rate and easy to install and maintain. Brushless excitation system is adopted, and the excitation device has automatic excitation throwing technology, automatic excision technology of demagnetization resistor, and lost-step re-step technology to ensure normal and reliable operation. The supporting excitation cabinet adopts fully digital circuit, with high reliability, strong anti-interference, low failure rate of main circuit control components and air-cooling system components, ensuring long-term operation. In the case of no shutdown and guaranteed load operation, the plug-in can be directly replaced and no more debugging can be done after the replacement. Custody, disassembly, maintenance is convenient.